A natural concern when operating a variable frequency drive system is the prevention of motor damage over time.

While VFDs can help to cut electricity costs by adjusting to match demand loads, the fluctuation of the electric current can have harmful effects on your system.

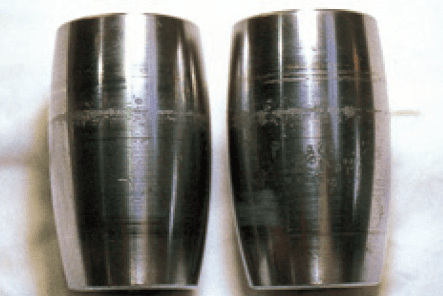

High frequency circulating currents produced by the variable frequency and voltage of these systems can result in motor bearing fluting, pitting, and frosting, lubrication breakdown, and electrical discharge machining (EDM). When preventing against motor damage and these unwanted effects, it is important to first understand what causes them.

Why Motors Fail

Electric motors fail for all kinds of reasons. Understanding the various causes and contributing factors will help you to troubleshoot and determine the appropriate solution for your system:

— Bad bearings – Bearing-related complications are the most common root cause of electric motor breakdown, resulting in more than half of all failures. Check for contamination, denting, scratching, or any kind of distortion, as this could lead to excessive endplay or vibration.

— Bad bearings – Bearing-related complications are the most common root cause of electric motor breakdown, resulting in more than half of all failures. Check for contamination, denting, scratching, or any kind of distortion, as this could lead to excessive endplay or vibration.

— Bearing currents – When a motor’s dielectric oil film breaks down, the voltage increases and begins surging through the lowest impedance path to the ground – the motor shaft.  The high frequency current flows over the bearings, resulting in EDM.

The high frequency current flows over the bearings, resulting in EDM.

— Inadequate grounding – Especially when dealing with the high frequencies of VFD systems, it’s crucial to provide a low impedance path for the current to flow to the ground without passing through the shaft. To some extent, bearing current is unavoidable — but preventing a high frequency flow will help to prevent the damage caused by EDM.

— High carrier frequency – While there is no magic number to determine the safest frequency range for your system, experts recommend adjusting it as low as possible without creating disruptive noise. Systems with higher carrier frequency will run quietly but will be more destructive to bearings over time.

How to Prevent Motor Damage

Even with a solid understanding of the causes behind electric motor failure, accidents can still happen. However, there are a few preventative steps you can take to be proactive about motor maintenance, ensure smoother system operation, and extend overall service life:

—  Measure the voltage – Analyzing the voltage passing through the motor shaft will help to predict the likelihood of future damage caused by EDM. Again, there isn’t just one “safe” zone for your system, but regularly charting the voltage will make it easier to recognize deviations when potential issues arise.

Measure the voltage – Analyzing the voltage passing through the motor shaft will help to predict the likelihood of future damage caused by EDM. Again, there isn’t just one “safe” zone for your system, but regularly charting the voltage will make it easier to recognize deviations when potential issues arise.

— Perform a vibration analysis – Another method of recognizing EDM is to analyze the vibrations caused by fluting and bearing degradation. Monitoring the vibration levels shortly after the initial installation will help with early detection of possible motor damage.

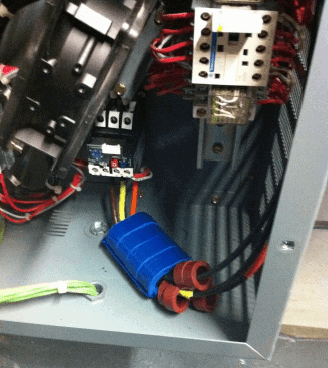

— Implement a “choke” mechanism – CoolBLUE® Inductive Absorbers are choke mechanisms that help to counter bearing failure. These inductors absorb the harmful high frequency currents and prevent them from flowing into circuits where they could cause damage to your system’s bearings.

For more information about preventing motor damage and the effects that such problems can have on your VFD system, contact Renown Electric today or check out this CoolBLUE case study to see how you can reduce motor bearing currents by over 65%.