A look at two recent CoolBLUE case studies for elevator motors.

Most modern elevator electric motors run via a variable frequency drive (VFD) for AC motors and DC controller (usually SCR based) for DC motors, which are used to control motor/elevator speed.

If you’ve read our motor bearing case study for electric motors, you know that motor controllers save up to 55% in energy costs, but they can also create a large amount of electrical and audible noise. This electrical noise manifests as “voltage spikes” (which is really Common Mode Current) that can cause a great deal of fluting, frosting, lubrication breakdown and other damage to the bearings.

Renown Electric Motors and Repair wanted to seek out and test for a solution to this problem in elevator motors. We investigated the use of CoolBLUE inductive absorbers, also known as common mode chokes, to learn how they could reduce the high frequency currents that VFDs and DC controllers produce — ultimately reducing or eliminating bearing damage to the motor.

The Plan – DC Motors

To test our theory, we used a Rogowski coil, a toroidal coil specifically tuned to measure high frequency current pulses that are superimposed on the control signal, on the output of a DC controller. This drive was connected to a Bull Gearless DC hoist motor in a busy Commercial Retail and Office Complex in downtown Toronto. The motor and drive are separated by approximately 20 feet of inverter duty cable.

Bull Gearless DC Hoist Motor

AC Motor without CoolBlue Coils

The Results

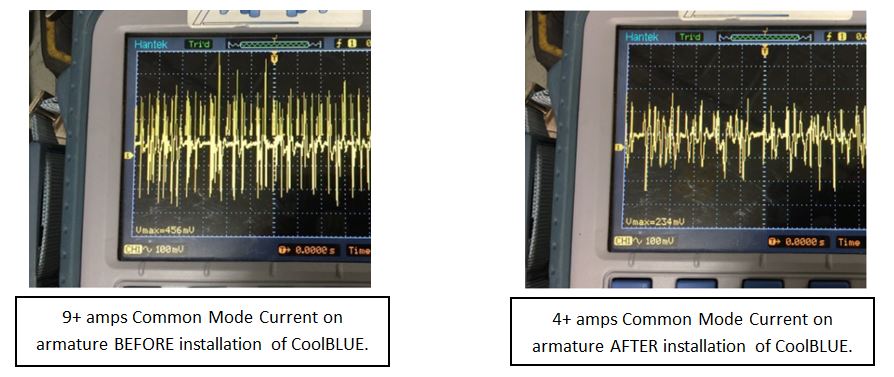

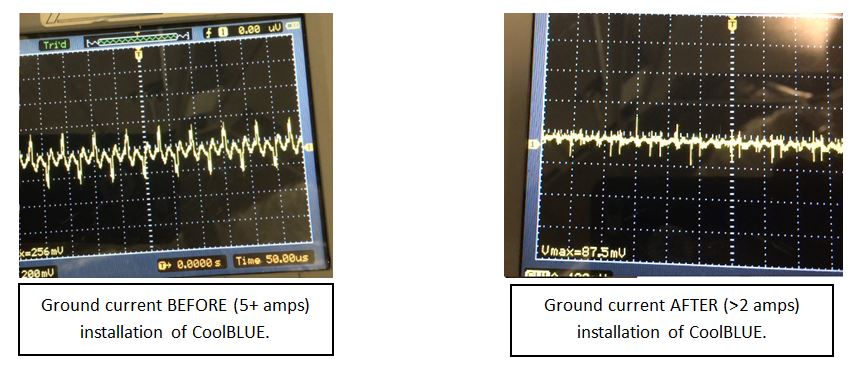

With the elevator running, we used an oscilloscope and the Rogowski coil at the drive output and measured high frequency current spikes greater than 9 amps going to the armature — see figures below — superimposed on the control signal for the elevator motor.

Tests conducted after installing CoolBLUE inductive absorbers and NaLA noise line absorbers clearly showed common mode current reduced by 5 amps at the drive output, a reduction of roughly 55%. Testing on the ground also showed with CoolBLUE and NaLA absorbers installed reduced current to below 2 amps, a 60% reduction. Both measurements well within the safe range for current density ratings of the bearings.

The Plan – AC Motors

We installed a Rogowski Coil (used to measure Alternating Current (A/C) and high speed current pulses) on the output of the VFD on an overhead geared traction machine with a 40HP AC Hoist motor to measure the actual electrical noise level caused by the switching of the IGBT’s.

The Results

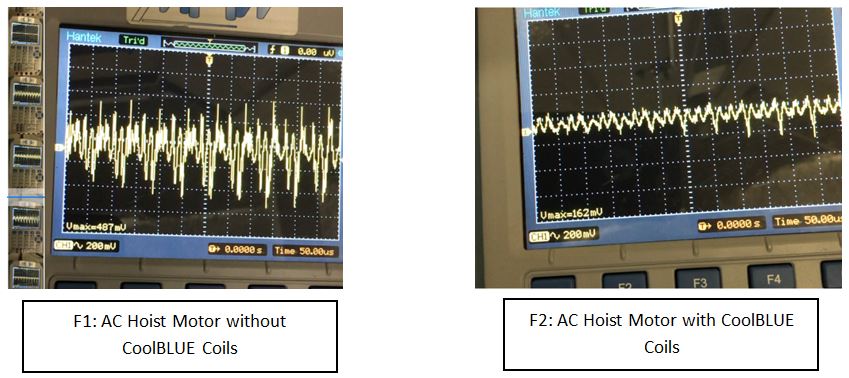

Typical results of the testing are in Fig. 1 and indicate a common mode current being introduced by the IGBT’s of nearly 10 amps superimposed on top of the control signal. As in the previous case, our oscilloscope is set up for millivolt (mv) capture and a converter is used on the Rogowski coil to convert amps to millivolts at 50mv/amp. Note that there were already ferrite chokes on the system in Fig. 1 however they did not measurably impact the noise level.

The CoolBlue inductive absorbers were installed onto the output of the VFD and the system electrical noise was reduced by approximately 65% to roughly 3 amps Fig. 2.

In this AC motor and drive application, we measured the common mode current on the output of the drive before and after installing CoolBlue and NaLA’s on the drive and achieved a reduction of 3 times (from roughly 9 amps to below 3 amps).

The Conclusion

After conducting tests of CoolBLUE inductive absorbers and NaLA noise line absorbers, Renown found that the absorbers perform very effectively to reduce common mode currents (“voltage spikes”) well within safe operating limits of the bearings.

We recommend optimizing the number and type of absorbers depending on the particular motor with which they are to be installed, and expect common mode current reductions in the area of 65%. The absorbers will effectively eliminate the damage that leads to harmful vibrations, extending the life of your motor bearings and reducing incidents of maintenance.

To learn more about CoolBLUE inductive absorbers and NaLA noise line absorbers, download our CoolBLUE Design and Installation Guides today.

CoolBLUE Absorbers

Download Design & Installation Guides