Blog

Is Your Motor Driving Up Costs and Creating Safety Hazards?

When your motor isn’t running properly, the business loses time and money — and you also risk the safety of your employees. When it comes to providing efficient, safe operation systems, Renown Electric has the resources required for success.

As highlighted in Renown’s latest case study, the company was recently approached by a rubber mill owner to help with operation repairs to their outdated control system. Renown’s industry knowledge and ability to implement an effective solution led to the successful restoration of the customer’s system.

Tackling Safety Risks

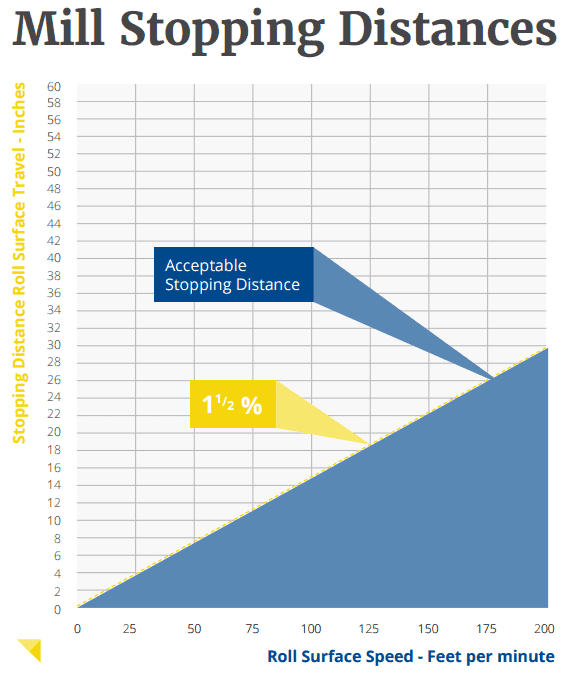

According to the Occupational Safety & Health Administration (OSHA) safety standards, mills are required to cease movement within specified limits. If these limits are not properly enforced, employees risk exposure to hazardous workplace conditions.

When the rubber silicone mill control and braking system was deemed antiquated, the customer needed quick, convenient assistance to restore operations. Not only did these braking complications slow down production and pose safety risks to the customer’s employees, but it also meant that the mill was not meeting essential OSHA requirements.

Minimizing Costs

To quell the safety hazards and production issues caused by the rubber mill’s outdated controls, the customer turned to Mann Electric. After a thorough assessment of the mill’s controls, and with the assistance of Benshaw Controls, Renown concluded that installing a new control panel would comply with OSHA’s strict safety standards.

By updating the mill’s aging machinery, Renown and the customer extended the motor’s lifetime and provided the customer with increased efficiency and long-term savings. Additionally, the teams were able to use the updated controls in conjunction with the mill’s existing braking resistors, allowing the mill to quickly halt production in emergency situations, as required by safety regulations.

To read more about Renown’s work with Mann Electric and the rubber mill, the full case study is available for download here.

Why Renown?

Founded in 1984, Renown Electric has a history of providing consumers with exceptional motor repair and maintenance services worldwide. Our expansive inventory contains both new and used motors and motor parts to support an array of applications. We pride ourselves on our ability to provide high quality services to a variety of customers across a range of industries.

If you’re experiencing decreased or inadequate performance from your equipment, contact Renown Electric today to learn more about how we can provide you with efficient, affordable service.

Comments are closed