Blog

Learn how inductive absorbers reduce damage to motor bearings and extend equipment life

This post continues Renown’s monthly series called “How It Works,” featuring articles that detail the inner workings of motor maintenance services and processes.

Electric motors are increasingly being equipped with variable frequency drive (VFD) systems for the energy efficiency the combination creates. This efficiency saves money both directly by reducing energy costs, and indirectly by increasing output.

Yet as most good things do, VFD systems have a small drawback: they create a considerable amount of unwanted high frequency currents to the motors in the form of motor bearing currents. Renown Electric recently partnered with MH&W International to offer a solution to this problem — CoolBLUE Inductive Absorbers.

Effects of VFD Vibration

The side-effect that is caused by VFD systems are actually generated by the IGBT’s switching frequency in their common-mode output. Created by the VFD itself, the unwanted current travels to a motor and its bearings via the motor leads that attach the VFD system to the motor.

When the common mode current reaches the motor, they travel through both the motor and its bearings in the form of motor bearing currents. These currents can be measured using a special instrument called a Rogowski Coil and an oscilloscope. These damaging currents cause a great deal of electrical noise and, more importantly, a laundry list of mechanical issues that collectively reduce the efficacy and lifespan of the motor:

— Bearing fluting

— Bearing frosting

— Lubrication breakdown

— Pitting

— Electrical discharge machining (EDM)

What are CoolBLUE Inductive Absorbers?

Inductive absorbers are more commonly known as common mode chokes. They are self-contained electrical inductors used to block and absorb — in other words, to choke — electromagnetic interference (EMI) and radio frequency interference (RFI).

Both common mode currents, EMI and RFI are the two causes of the EDM effect in bearings created by VFD systems. They do this without blocking differential currents, the currents passing through the power cables that are required to power and control the motor.

Unlike dv/dt filters, designed to limit voltage spikes in long lead length applications, CoolBLUE cores are designed to specifically choke off the unwanted high frequency currents that are created by the switching of IGBT’s and SCR’s. This frequency is in the order of 500 kHz to several MHz whereas your control frequency is in the range of much lower kHz.

CoolBLUE Inductive Absorbers do not block all of the EMI and RFI currents, but they do restrict the majority of them — between 65% and 80%, which is more than enough to prevent them from damaging your motor. When installed properly, CoolBLUE Inductive absorbers will reduce common mode currents.

How to Use CoolBLUE

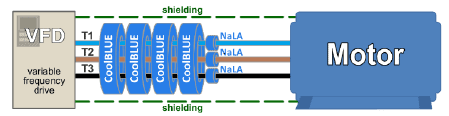

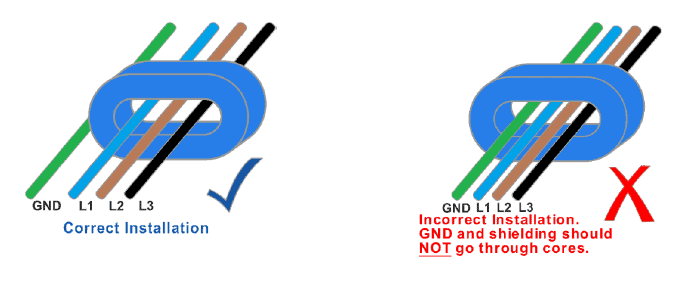

CoolBLUE Inductive Absorbers are extremely simple to install. Disconnect the power cords between the VFD and the motor, insert the phase cords thru the applicable cores — always exclude the grounding wire, leaving it out of the CoolBLUE mode chokes — and reconnect the power cords. The photos below show a few example CoolBLUE installations.

Some installation considerations to keep in mind:

— CoolBLUE units can be installed on AC, DC, Permanent Magnet motors and Servo Applications

— Keep the chokes as close to the VFD as possible

— Install NaLA Noise Line Absorbers for added protection

— Loop motor leads twice through the CoolBLUE chokes for smaller applications between 1/4hp and 10hp

CoolBLUE from Renown

Renown Electric is proud to offer the full line of CoolBLUE Inductive Absorbers to help you to extend the life of your motor today.

To learn more about CoolBLUE chokes, download our free Design and Installation Guides today.

Comments are closed