One way to stay ahead of motor malfunctions is to employ Motion Amplification® monitoring solutions. Motion Amplification is a proprietary video processing algorithm that—when combined with video cameras—amplifies subtle movements to make them visible to the naked eye. When used for motor systems, it can provide equipment technicians a more complete picture of equipment performance and condition.

As a certified service provider for RDI Technologies, Renown Electric is well-aware of the benefits of the innovative technology. Adopt a Motion Amplification monitoring solution to extend the working life of an Electric Motors & Generators today!

Visualize Complex Vibration Problems Invisible to the Naked Eye

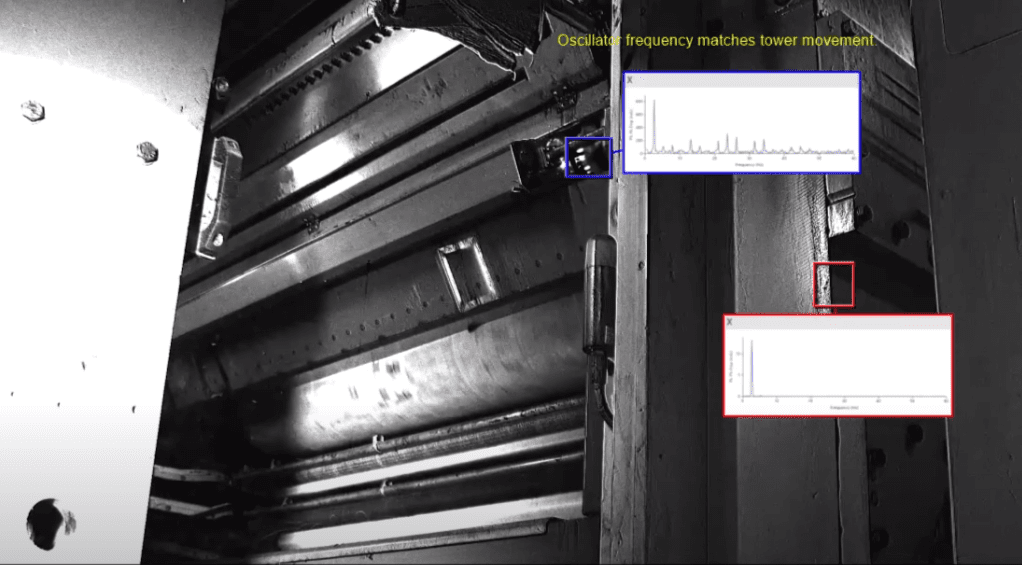

Motion Amplification solutions do more than output information about a motor system—they allow industry professionals to see the intricate and minute movements occurring within the equipment.

While other monitoring solutions might provide static magnifications or point measurements, only they offer real-time visualizations of system performance alongside any meaningful information extracted by the processing software. This characteristic enables a better understanding of the different motor components and the relationships between them that, in turn, translates to a better understanding of the system as a whole. The insight obtained makes it easier for industry professionals to identify if and when things go wrong and implement targeted and cost-effective solutions accordingly.

When used optimally, Motion Amplification technology can save both time and money regarding vibration analysis, routine monitoring, and troubleshooting, root cause analysis, and other maintenance and repair operations.

Make Monitoring Safer & Easier With Non-Contact Measurement

In addition to facilitating monitoring and maintenance operations, employing a Motion Amplification solution substantially decreases the risk of injury to life and limb for employees.

Malfunctioning equipment carries the risk of damaging other equipment and injuring employees. For motors suspected to be malfunctioning, manual maintenance and inspection operations bring service technicians closer to the danger. Employing Motion Amplification technology, however, allows them to measure and quantify equipment movement without coming into direct contact with the motor.

The technology’s non-invasive design facilitates the identification and documentation of motor condition through a high fps, high-resolution camera—rather than physical means. A sophisticated video processing algorithm then analyzes the visual data to output metrics and a visual representation of the movement. In this way, technicians gain access to a wealth of monitoring data without needing to go near a potentially hazardous system.

The elimination of physical contact in no way diminishes accuracy. Despite being taken from a distance, the measurements collected by Motion Amplification systems are at the same level of accuracy as those of standard contacting displacement sensors.

Prevent Costly Motor Repairs and Replacements

Over the service life of a motor, Motion Amplification systems can save significant amounts of time and money. By enabling the detection of potential issues and identifying failure points, they allow technicians to implement appropriate solutions before the motor is significantly damaged and requires more costly comprehensive repairs or needs complete replacement.

Where other monitoring systems may fail, Motion Amplification systems can detect even the slights deviations from normal operations. This quality makes them well-suited for use in regular diagnostics and preventative maintenance procedures as well as troubleshooting and root cause analysis operations.

Some examples of common errors that these systems can help identify and diagnose include:

- Imbalance

- Looseness

- Misalignment

- Resonance

- Soft foot

- Structural cracking

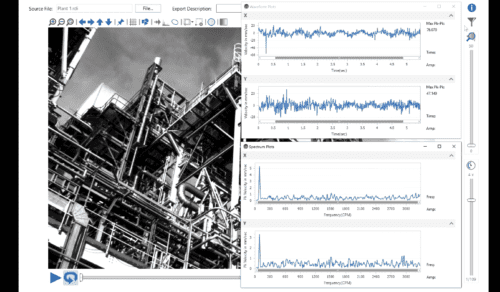

Manage All of Motion Amplification Data From One Place

When it comes to monitoring and troubleshooting, it’s important that equipment records be organized and easily accessible. It’s not enough to rely on one-off measurements or incomplete date sets as they generally do not provide a full picture of a motor’s performance and condition history. A comprehensive record is needed to accurately monitor and track a motor’s performance and identify if and when an issue may arise.

When it comes to monitoring and troubleshooting, it’s important that equipment records be organized and easily accessible. It’s not enough to rely on one-off measurements or incomplete date sets as they generally do not provide a full picture of a motor’s performance and condition history. A comprehensive record is needed to accurately monitor and track a motor’s performance and identify if and when an issue may arise.

Motion Amplification systems monitor and track equipment issues and store all of the data together in a hierarchical structure. The recorded videos are saved together with links to associated files, including reports and other key data. This organizational system allows service technicians to track the status of an Electric Motors & Generators over time and makes it easy to access relevant information when it comes time to troubleshoot a problem.

Renown Electric: Experts in Motor Repair and Replacement

Renown Electric is a leading provider of repair and replacement services for Electric Motors & Generators. Equipped with nearly four decades of industry experience, we fully understand the complexities and challenges of keeping Electric Motors & Generators running at their best, especially when some threats to performance are invisible.

Our recent partnership with RDI Technologies allows us to provide services using their Motion Amplification product solutions. Safe, accurate, and cost-effective, the technology enhances our ability to help monitor and troubleshoot motors for our customers.

Contact Us today for more information on our Motion Amplification solutions and how they can benefit your company’s Electric Motors & Generators.

Contact Us today for more information on our Motion Amplification solutions and how they can benefit your company’s Electric Motors & Generators.

We invite you to download our recent free eBook, The Key Benefits of Motion Amplification Monitoring for Your Electric Motors & Generators