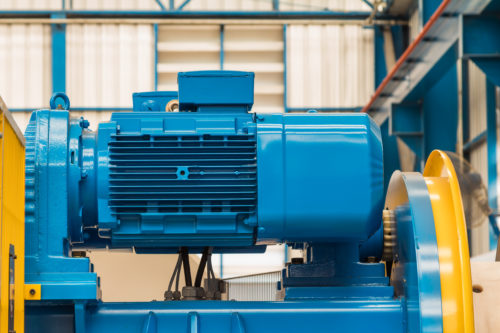

Whether you need one-stop shop electric motor repair services, preventative maintenance for your pump or motor or a service visit from an engineer, Renown Electric does it all.

Our comprehensive analyses and tests for electric motors help your business avoid problems and downtime. If an electric motor or system needs repair, our team will come to you or fully service the rebuild in our own facility. We help businesses in our service area throughout Canada and the United States every day!

Electric motors play a critical role in a wide range of industrial, municipal and commercial operations. When electric motors start showing signs of failure, facility managers face a tough decision: repair or replace?

Electric motors play a critical role in a wide range of industrial, municipal and commercial operations. When electric motors start showing signs of failure, facility managers face a tough decision: repair or replace?

Repairing the motor may provide a quick fix that keeps your business running smoothly, but its long-term reliability and efficiency are uncertain, risking future failure. On the other hand, replacing the motor may be more costly and time-consuming, but it often ensures longer-lasting equipment. Having a repair/replacement plan in place before motor failure occurs is crucial. This plan streamlines decision-making, allowing informed choices between repair and replacement without being swayed by short-term goals like minimizing downtime. Consulting with your electric motor repair shop and vendors can offer valuable insights to address application-specific issues, with resolutions designed or modified during the repair process.

Here are some general guidance to think about when looking at the repair vs replace decision process, along with the specifications to keep in mind when planning a repair operation using the motor repair capabilities at Renown Electric.

Preventative & Predictive Maintenance Services

Avoid downtime and repair or replacement costs by investing in preventative maintenance before it’s too late. Preventative and predictive services we offer include:

- Dynamic Balancing

- Infrared Thermography

- Oil Analysis

- Laser Alignment

- Vibration Analysis

- Winding Analysis

Find out more about each offering by choosing a service above or visiting our preventative and predictive services page.

Field Services

Let us come to you for electric motor repairs. Our experienced technicians can perform electric motor repair—including service support for the elevator industry—as well as remanufacturing and preventative maintenance in locations throughout Canada. Here are our field services available:

- Brush Survey

- In-Field Rewinding

- Modernization Survey

- On-Site Machining

- Sheave Regrooving

- Turning and Undercutting

Find out more about our individual field services by choosing one of the above. Or visit all of our field services information.

Shop Services

Get access to a number of motor repair and diagnostic services at our modern 25,000-square-foot facility. Find out what these in-house services are below:

- Electric Motor Rewinding and Rebuilding

- Generator Rebuild and Rewinding

- Gearbox Rebuild and Rewinding

- Sheave Regrooving and Manufacturing

- Machine Shop Services

- Servo Motor Repair

- Pump Repair

- Motor Drive Repair

Find out more about specific shop services by clicking each of the links above or visiting our motor repair shop services page.

Key Considerations for Deciding Between Electric Motor Repair or Replacement

As a general rule of thumb, if the cost of repairing an existing electrical motor is more than 65% the cost of replacing it with a newer unit, replacing the unit is considered more cost-effective. The price differential between repair and replacement may be quickly recovered if the new component has higher efficiency. While the above serves as a general guideline, as indicated above, deciding whether a failed electric motor should be repaired (i.e., rewound) or replaced is not as straightforward as it may seem. There are numerous factors to consider when evaluating whether a repair or replacement operation is more appropriate, such as the cost of repair or replacement, the performance of the component, the load factor, the facility’s operating hours, and the electricity usage. Review of the application may be required to determine if a better motor design or modified design may improve mean time between failures. Some of the other considerations to keep in mind when determining the overall effectiveness and efficiency of repair vs. replacement are:

Motor Design

For special purpose motors with highly specific or unique designs, it may be better to repair rather than replace the motor since a replacement may not fit or perform in the same way. Finding a like-for-like replacement for a motor that is obsolete or no longer in production may not be possible. Therefore, repairing the motor is the only viable option in this case. Having a reputable firm known for high-quality electric motor repair services is a must in this situation.

Motor Age

Historically, DC and AC motors were designed for service lives up to and exceeding 25 to 35 years with the potential to last even longer. Today, motors are built to last between 15 to 20 years, after which they will require overhaul. These ranges should serve as a benchmark for whether it would be better to repair or replace a failed component. If the unit is at the lower end of the range, then repair is still a feasible option, but if it is at the upper end of the range or the process may change or retooled, then it could be wiser to invest in a new system.

Motor size

In addition to the durability and longevity of AC and DC motors, the size of motors has changed over time. Newer models are smaller than older models, which can make replacing existing units challenging. Along with size changes came starting torque and slippage changes, these factors need to be considered carefully as they can impact system performance, power consumption and operational efficiencies.

Electrical Motor Repair Requirements

While some motors can be repaired or rebuilt by any motor servicing shop, others may need to be sent back to the original equipment manufacturer. Motor shop quality and repair standards are another factor that need to be considered. Repair equipment used in the motor rebuild process needs to be calibrated to ensure a repaired motor is returned to its original design efficiencies. A motor repaired to less than nameplate efficiency will cost more to operate in the long run, and you may lose any cost savings anticipated by repairing the motor very quickly. Proper motor repair can increase the cost and length of a repair operation, making replacement the more efficient option however a motor running efficiently will quickly pay for itself.

Lead Time

As mentioned above, the time it takes to implement a solution influences whether it is appropriate for the facility’s needs. The lead time for a new or repaired component should be minimized to reduce the impact on operations. Over the years, the introduction of new government regulations (e.g., the Energy Independence and Security Act of 2007) prompted motor manufacturers to make changes to the design, construction, and performance of their units. These changes influenced a variety of motor qualities, such as the motor inrush (up to 13 times the full-load amperage vs. 6–7 times the FLA) and slip speed (less slip in EISA motors). These factors should also be considered when faced with the decision to repair or replace an older motor.

Important Specifications for Electric Motor Repair Operations

Once the appropriateness of repair has been determined, it is important to communicate the necessary information to the service provider to facilitate shorter lead times. In addition to obtaining records about the motor’s current condition and performance and maintenance history, the repair shop should receive specifications that clearly indicate the expectations for the repair operation, including the following:

- The intent and scope of the operation

- The relevant standards

- The repair procedures

- The testing and quality control procedures

By having this information, the repair shop is better able to ensure the repaired motor meets the specific needs of the facility.

Motor Repair Services at Renown Electric

If and when a motor fails, it is essential to work with an experienced and knowledgeable repair shop to ensure the component motor successfully returns to its original condition. At Renown Electric, we’ve provided in-house and in-the-field electric motor repair and maintenance services for over three decades. In addition to our electric motor rebuilding and rewinding shop capabilities, we offer the following services:

- Generator rebuilding and rewinding

- Gearbox rebuilding and overhaul

- Sheave regrooving and manufacturing

- Machine shop services

- Coil manufacturing

- Pump repair

- AC & DC Motor control and drive repair

For additional information about our service offerings and how they can benefit your facility, contact us today.

Our wide range of preventative and comprehensive motor repair services have been performed on many different motors and systems over the last 30+ years in business. We serve a variety of industries, including elevator systems, energy and power, automotive, industrial manufacturing, wastewater management, and much more. We do so successfully with our multiple certifications that allow us to provide quality services. Some of these include ISO 9001:2015 and CSA Qualification for Repair and Service of Motors and Generators in Hazardous Locations. Contact Our Team today to hear more about our services, or to schedule an appointment. Let our experts perform your motor repair services.