In recent years, dairy farmers have been making increasing use of radio frequency identification (RFID) tags to easily keep track of their cows and overall milking output.

Embedded into or glued onto a standard cattle ear tag or worn around the cows ankle, RFID tags allow farmers to track the specific whereabouts of any given animal at any given time, while also providing critical information on the overall health of each animal, particularly in regard to disease exposure; the milking cycles of calves; overall milk production; and various parameters for yield increase.

With all of this information available to dairy farmers in real time, maintaining the health of cows and, consequently, the volume and yield of their milk, is now easier than ever. To better illustrate how RFID technology works, we’ve outlined a case study below.

Case Study: Dairy Farm RFID Issues

Renown Electric was recently approached by a dairy farm experiencing issues with their new RFID system.

After affixing RFID tags to the existing ear tags of each of their cows and installing a control computer, a range of RFID readers at strategic locations, and other critical equipment, they booted up their new system. Things were progressing smoothly, and only one or two cows per shift were going unidentified — a small number well within acceptable ranges for a new system considering there are over 400 head of cattle in this facility. The farmer was collecting valuable data on animal movement, health, and milk production.

However, shortly thereafter, the RFID system began to fail. Where previously only one or two cows were missed per milking shift, now eight or more cows were being missed. In turn, the data began to suffer. The team at the dairy farm called Renown for help in diagnosing the issue.

The Problem

After hearing from the farmer, Renown Electric began to investigate the issue. Upon touring the farm, inspecting the RFID infrastructure, and asking relevant questions, it was determined that the farm had recently upgraded its liquid manure aerator — a large piece of equipment used to aerate liquid manure, which is then used as a fertilizer.

This equipment is very useful for farm operations, as it both reduced the odor from the manure and improved fertilizer quality. But it also requires high energy consumption and is expensive to operate. The recent upgrade was to add a variable frequency drive (VFD), a type of adjustable-speed drive to reduce energy consumption and improve aeration.

VFDs use a switch — usually an insulated-gate bipolar transistor (IGBT) — to convert a controller’s digital signal to an electric signal that an electric motor can use. VFDs help to increase the energy efficiency of electric motor systems, which is important for a high-energy aerator, but they also create byproducts — high-frequency currents which can be damaging to motors and cause currents to run across the motor to ground.

These currents, known as common mode current, were interfering with the farm’s RFID system, disturbing the frequency of the RFID tags and leading to missed readings.

The Solution

To solve this issue, the Renown Electric team made use of CoolBLUE Inductive Absorbers, a variety of self-contained inductors known as common mode chokes. These absorbers block and absorb, or “choke,” the unwanted frequencies generated by the IGBT or other switches found within variable frequency drives.

Once installed on the leads from the VFD leading to the aerator motor, the CoolBLUE Inductive Absorbers greatly reduced the electrical noise that was causing the interference affecting the RFID system. The farm’s RFID tag system is now working smoothly and efficiently, missing only one cow per week, rather than eight per milking shift.

Learn More

To learn more about CoolBLUE Inductive Absorbers and how they can help solve your RFID problems, download our comprehensive design and installation guides, or reach out to the team today.

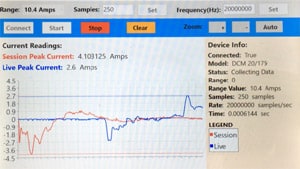

Before

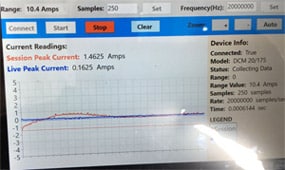

Before After

After