Blog

In recent years, variable frequency drives (VFDs) — motor controllers that drive electric motors by varying the supplied frequency and voltage — have become more and more popular thanks to their superior performance, high potential energy savings, and low operating costs.

Despite these benefits, however, VFDs can also cause significant motor bearing damage in just a short period of time.

By controlling both speed and torque, VFDs can greatly improve motor efficiency. In order to do so, they run digital signals from a microprocessor-based controller through a switch, which converts it to a usable electrical signal for the motor.

This results in significant voltage spikes that seek out the quickest pathway to the ground — often through the motor bearings. This can cause bearing current damage in the form of fractures and fluting, ultimately leading to motor failure and production downtime.

How to Identify Bearing Damage Symptoms

There are a few warning signs that indicate ball bearing damage. Audible chattering coming from the motor bearing is one of the most obvious, and, unfortunately, one of the later-stage symptoms. A noisy motor indicates advanced bearing failure and demands immediate attention and production shutdown.

Less obvious visual signs include dark lubricant — a result of burning or metal particles getting lodged in the bearing as a result of the high frequency currents — as well as fluting, a perpendicular series of lines across the bearings caused by the electrical flow. A “smoky” or dull appearance of balls or bearings is an indication of microscopic pitting of the metal by the current.

Solutions

Manufacturers have various proactive approaches at their disposal to prevent motor shaft voltage and bearing current damage.

Performing a vibration analysis at the first sign of fluting, for instance, can help prevent further damage, while monitoring shock pulses and bearing temperatures allows users to gauge whether any current can be directed away from the bearings.

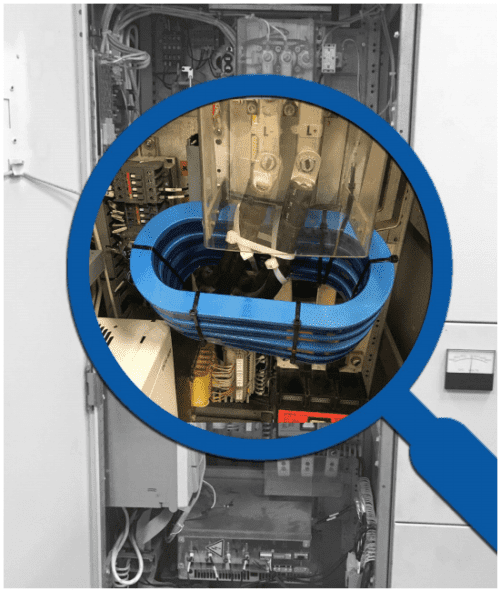

Installing common mode chokes, however, can actually prevent damage from the outset.

These components, also known as inductive absorbers, are specifically designed to reduce electrical surges and the harmful effects of discharge. By blocking (or choking) particular frequencies, they help to lower the voltage spikes that can quickly destroy your bearings.

Want to Learn More?

At the forefront of electric motor distribution and repair services, Renown Electric is proud to serve a diverse range of customers and industries. With over three decades of experience, we understand the importance of protecting your Motor systems and minimizing production downtime.

To learn more about how protect your ball bearings and motors, check out our new eBook, “Avoiding Motor Shaft Voltage & Bearing Current Damage.”

Comments are closed