The oil and gas drilling industry is one of the biggest industries in the world, generating trillions of dollars in global revenue per year. Oil and gas extraction occurs in all environments throughout the world, both onshore and offshore. Quality, top-performance electric motors and generators are crucial in maintaining onshore and offshore drilling operations.

Motors and generators for oil and gas drilling applications must be reliable, durable, and able to withstand harsh environmental conditions. At Renown Electric, we understand how motors and generators are used throughout this industry, and we can deliver quality solutions to ensure optimal performance.

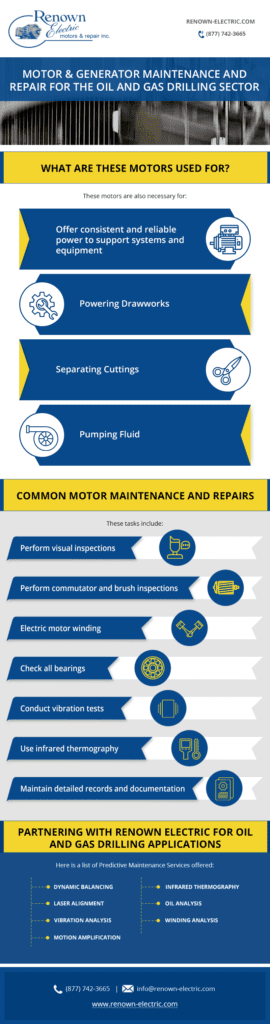

The Importance of Electric Motors and Generators for the Oil and Gas Drilling Industry

Electric motors and generators play a number of key roles in the oil and gas drilling industry. Electric motors offer consistent and reliable power to support systems and equipment used for extraction, processing, transportation, and storage of various gas products, including petroleum, natural gas, and crude oil. These motors are also necessary for powering drawworks, separating cuttings, and pumping fluids.

Other components that rely on electric motors and generators include drive pumps, air compressors, fans, and other equipment frequently used in the oil and gas drilling industry. Specifically, products such as synchronous generators, induction motors, and pump motors provide power for onshore and offshore drilling operations.

Common Electric Motor Maintenance and Repairs for Oil and Gas Drilling Operations

Since electric motors and generators are crucial for the oil and gas drilling industry, it is essential to maintain a preventative maintenance plan to ensure optimal efficiency and safety of the equipment. Proper maintenance boosts equipment lifespan and significantly reduces the risk of premature equipment failure which can lead to costly downtime. Equipment used for this industry is exposed to conditions such as consistent vibrations, extreme temperatures, and corrosive substances, further necessitating regular maintenance and repairs.

Preventative maintenance should be conducted on a regular basis to ensure peak performance. It is also important that all maintenance tests and procedures be performed systematically to discover potential issues and correct them before they have a negative impact on operations.

When performing maintenance and repairs for electric motors and generators, it’s important to:

- Perform visual inspections

- Perform commutator and brush inspections

- Conduct motor winding tests

- Check all bearings

- Conduct vibration tests

- Use infrared thermography

- Maintain detailed records and documentation

Partnering with Renown Electric for Oil and Gas Drilling Applications

The team at Renown Electric has provided motor repair services to a wide range of industries for decades, including the oil and gas drilling industry. We offer motors and generator repairs for both offshore and onshore platforms from fractional HP through 50,000HP in all voltage ranges up to 13,800 Volt.

Renown Electric is a one-stop shop for all of your electric motor management needs. We also offer preventative maintenance services to prevent costly issues for your oil and gas drilling operations. These services include:

- Dynamic Balancing

- Infrared Thermography

- Laser Alignment

- Oil Analysis

- Vibration Analysis

- Winding Analysis

- Motion Amplification

For more information about our electric generator and electric motor repair capabilities for the oil and gas drilling industry, contact us today.